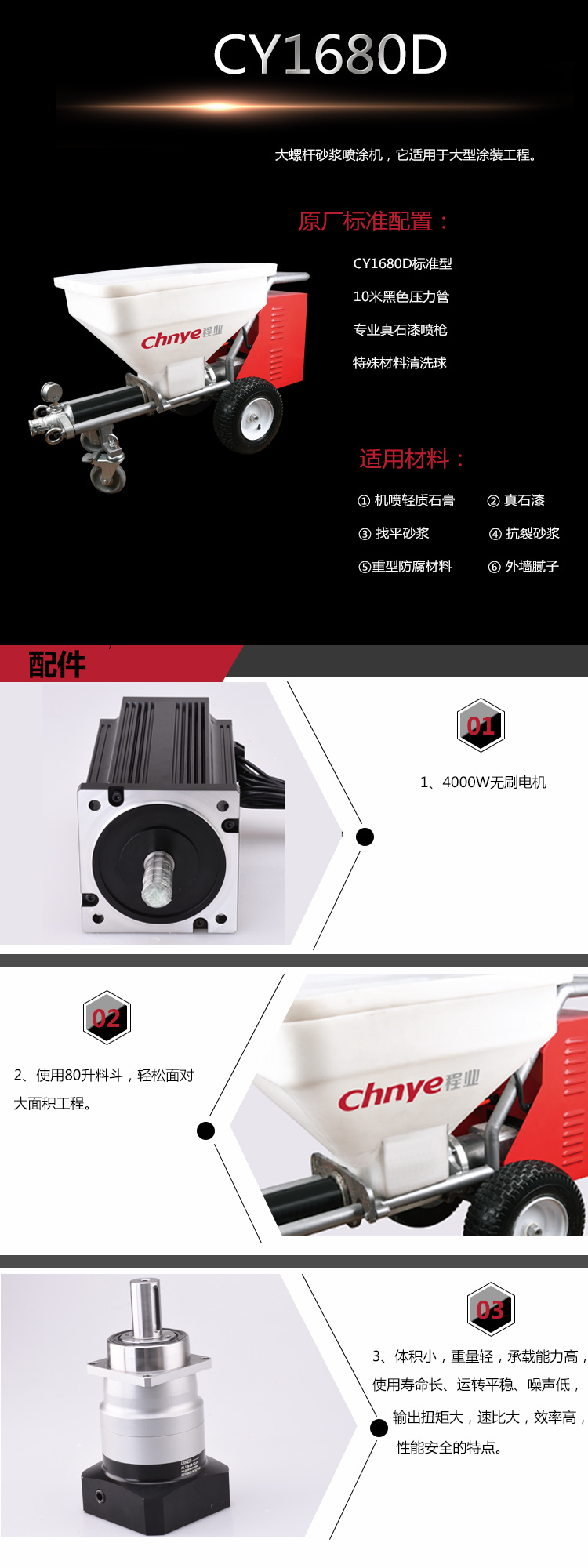

Airless Sprayer CY1680D

Specialized in manufacturing airless spraying equipment, non-curing sprayer, waterproof coating sprayer, airless sprayer, polyurethane waterproof sprayer, putty sprayer, waterproof sprayer, polyurethane sprayer.

Key words:Airless Spraying Equipment丨Non Curing Sprayer丨Waterproof Coating Sprayer丨Airless Sprayer丨Polyurethane Waterproof Sprayer丨Fat Putty Sprayer丨Waterproof Sprayer丨Polyurethane Spraying Machine

Hotline:

Airless Sprayer CY1680D

The airless sprayer uses a plunger pump to pressurize the paint, and the high-pressure paint is transported to the spray gun through a high-pressure hose , and the pressure is released through the nozzle to form atomization, thereby forming a dense coating on the wall surface.

Airless spray machine principle

The air-assisted airless sprayer mixes compressed air at the atomization point of the paint to further refine the paint. The compressed air (0.2-0.5 MPa) atomizes the paint. The airless sprayer sprays onto the surface of the object to form a paint film. The pump pressurizes the paint (about 21 MPa), sprays atomization from the nozzle, and sprays it onto the surface of the object to form a paint film. Use a pump to pressurize the paint (about 21 MPa), spray atomization from the nozzle, and spray it onto the surface of the quilt to form a paint film.

Efficiency 400-600 square meters/hour

3200-4800 square meters/day Hand brushing: 60-80 square meters/person*day Roller brushing: 150-200 square meters/person*day 200 square meters/person*day 3200-4800 square meters/day

400-600 square meters/hour

Airless sprayer features

The airless spray machine is highly efficient 1. The coating efficiency of roller brush is slightly higher than that of hand brush, but both are lower; 1. More efficient than manual labor

Air is mixed into the atomization point of the paint in the airless sprayer, and the paint molecules are further refined 2. The surface of the paint film is not smooth; there are brush marks and spots. 2. The paint contains air molecules, which causes the paint to scatter and seriously pollutes the environment. 2. There is no air in the paint molecules, so there is less scattering

The paint is sprayed out under pressure and mixed with air, so there is no scattering and the surface is smoother. 3. It is difficult to treat curved surfaces with roller brush 3. The paint loss is more 3. Pressurized spraying of paint with strong adhesion and penetration

The coating film thickness is uniform and delicate. 4. The paint film is thin and requires multiple sprays to reach the required thickness, which affects the effect 4. According to different requirements, replace the nozzle to achieve the required film thickness at one time, and the coating will be uniform and delicate.

The spraying distance is 0.3-2 meters from the surface of the object. There is little paint mist splashing and no impact on the vision and health of the oil worker. No distance of 0.1-0.15 meters from the surface of the object. Severe paint mist splashing, even if wearing a gas mask and protective clothing, has no impact on the vision and health of the oil worker. The physical impact is greater. The distance from the surface of the object is 0.3-2 meters, with less paint mist splashing and no impact on the oil worker's vision and body.

Paint transfer rate: 85%, 90%, above 40%, around 70%

The pollution situation is environmentally friendly, and the slightly polluted paint will not atomize. It uses high-pressure air to atomize the pollution-free paint, and the serious pollution will cause less pollution.

Small labor intensity and small size

Paint adhesion is generally poor and strong

Related Products

Product Message

View mobile version

JIANGSU CHENGYEI TOOLS CO., LTD

Address: East of Maojiagang Border Police Station, Lvsi Town, Qidong City, Jiangsu Province

Telephone: 86-513-68039888

Mobile: 86-18806285688

Mailbox: phil@chnye.cn

copyright©2024 JIANGSU CHENGYING TOOLS CO., LTD